Page 2 of 3

Re: Measurements for fingers?

Posted: Fri May 13, 2011 9:18 pm

by Pat Comeau

Storm...i was gonna reply on your first changer pics dimensions

but i noticed it after looking at it real good that you've made a mistake on the measurements

, the second pics and dimensions are more standard

.

i use 5/16 " for the pull rod holes instead of 1/4"

Re: Measurements for fingers?

Posted: Sat May 14, 2011 3:53 am

by Jeffrey

Bent wrote:Jeffrey, My opinion is that the wraparound is the best. Why? because it gives you more throw on the finger and this in turn makes for a greater possibility of achieving those lowers that require a great throw(like lowering the 3rd G# a whole tone)

Hi Bent,

Thanks for the help. Yea, the wraparound seems sturdier to me, so I think I like it better, too. And i'm glad to hear about the throw. I was pretty sure that I'd have to custom fit the fingers to my build, but things like the spacing between the pulls and the approximate spot to drill for the rivet were more of the concern. I figured that, if I wasn't close with the rivet, the pivot point would be off and then so would the throw. Stormy gave me something that I could study while I draw up my own. That was cool of him!

If you don't mind another question... I looked at the photos of your work and was wandering, how are you getting those really nice bends on the fingers where the pull holes are drilled? Everything I've seen of yours is great work. You seem to be a natural at it!

Thanks again,

Jeffrey

Re: Measurements for fingers?

Posted: Sat May 14, 2011 4:06 am

by Jeffrey

Storm Rosson wrote:

Jeff ,I totally screwed up on the last pic/measurements .Here is the corrected dimension/pic....Stormy

Stormy,

There's no need for "oops", you totally came thru for me! Thank you! I figured out the different measurement after looking at it a bit

. The pic gives me what I needed to start working with... Something to reference. Now to just start my drawings, like Bent And Richard recommended, and fix my bandsaw (the rubber flew off the bottom wheel) and I'll be ready to start whipping out mistakes

. I generally make a couple dozen before I hit on what I meant to do.

Thanks for the help,

Jeffrey

Re: Measurements for fingers?

Posted: Mon May 16, 2011 9:47 am

by Dave-M

It's probably a good idea to make a finger test setup for one string prior to making a whole set of fingers, using some screws or bolts in a plank for axels and stops, similar to Mac's setup.

CLICK HERE

When determining rod spacing, (and even finger spacing), make sure your tuning tool clears adjacent tuning nuts.

Re: Measurements for fingers?

Posted: Mon May 16, 2011 10:50 am

by richard37066

Stormy -

NOW ya got it! Your measurements compare favorably with the changer on my GFI D10. Seems like we must yield to "accepted practice" since some folks had that sorted out some time ago.

Richard

Re: Measurements for fingers?

Posted: Mon May 16, 2011 1:09 pm

by Storm Rosson

Yep, pretty much my thoughts too Richard....Stormy

Re: Measurements for fingers?

Posted: Mon May 16, 2011 9:03 pm

by Bent

Jeffrey wrote:

If you don't mind another question... I looked at the photos of your work and was wandering, how are you getting those really nice bends on the fingers where the pull holes are drilled? Everything I've seen of yours is great work. You seem to be a natural at it!

Thanks again,

Jeffrey

Jeffrey, thanks! Here is how I do the bends:

First I got a 3/16" 90 deg V-groove cutter for the mill and cut a V-groove about .030 deep. Without a mill this can be done different ways: Try cutting a shallow cut with the hacksaw. Or, if you have a Dremel, chuck the cutting disk into it and cut a straight line. This won't make a V groove but a square one. Still it should help you make a nice bend.

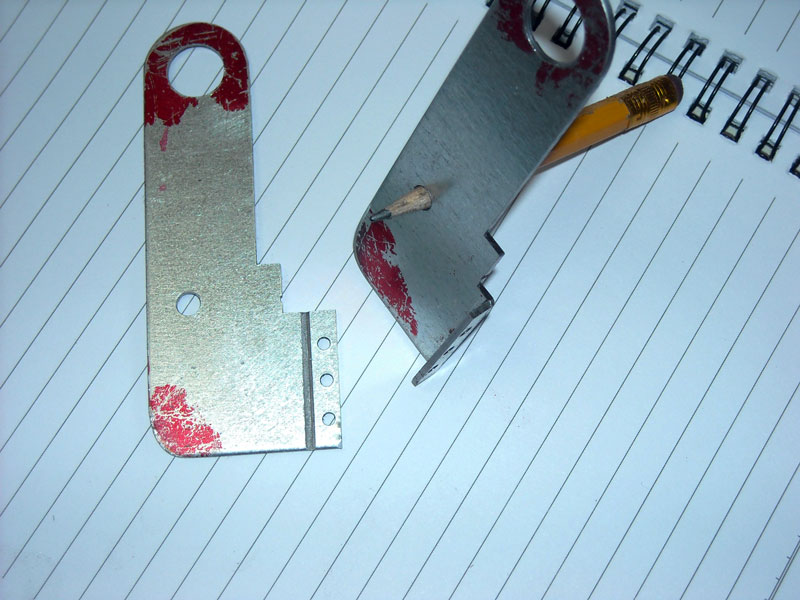

- bendfinger1.jpg (95.52 KiB) Viewed 2076 times

Then I set the piece in the vise like so...with the groove visible above the jaws and make a starting bend by hand:

- bendfngr2.jpg (78 KiB) Viewed 2076 times

Then I finish it off with the hammer. It works ok if you have square tops on your vise. You can also use Vise Grips with the wide flat jaws. I believe that would be better and less prone to mistakes

- bendfngr3.jpg (89.15 KiB) Viewed 2076 times

Re: Measurements for fingers?

Posted: Tue May 17, 2011 6:08 am

by Jeffrey

Dave-M,

Thanks for the suggestion! Building a test board will save me a lot of grief! Haha!

Bent,

Once again, you come thru with the good stuff! Thank you for the explanation, and the pics, too! You are quite a craftsman. Question, though... Does the v-slot seem to weaken the bend at all? Or does it seem just as sturdy as "just bending it"?

Again, thank you.

Jeffrey

P.S. Do you think you'll ever CNC your mill?

Re: Measurements for fingers?

Posted: Tue May 17, 2011 8:14 am

by Dave-M

Poking my nose in again, guys! I think in an all-pull, the bend is pulled into the V-groove, so would be sturdy enough with sections binding together. If you pushed it, though, there might be a tendency to push the flap off, or at least open the bend a bit.

In my opinion, a rectangular groove would not bind together quite as well as a V-groove. It could be shaped with a small square file with one edge down after sawing, though, or made with the saw at 45 degrees.

Re: Measurements for fingers?

Posted: Tue May 17, 2011 9:49 am

by Bent

Jeffrey, No it doesn't weaken the joint. There is still about 1/32" left of metal. Plus with the groove on that side, the "ear" gets pulled into the joint so the stress is in the right place. Plus I have tried to bend/break by over-stressing. Impossible, you bend or break the metal first.

Dave, you are correct on all points., also on the square groove vs the angled one.

One other way to do this without a mill at your disposal would be to buy a cutter and chuck it in your drill press. Hold the piece in a vise that slides two ways. Then run your drill press at the highest speed. Essentially there you have your milling machine, which in reality is just a glorified drill press.

but i noticed it after looking at it real good that you've made a mistake on the measurements

but i noticed it after looking at it real good that you've made a mistake on the measurements  , the second pics and dimensions are more standard

, the second pics and dimensions are more standard  .

.