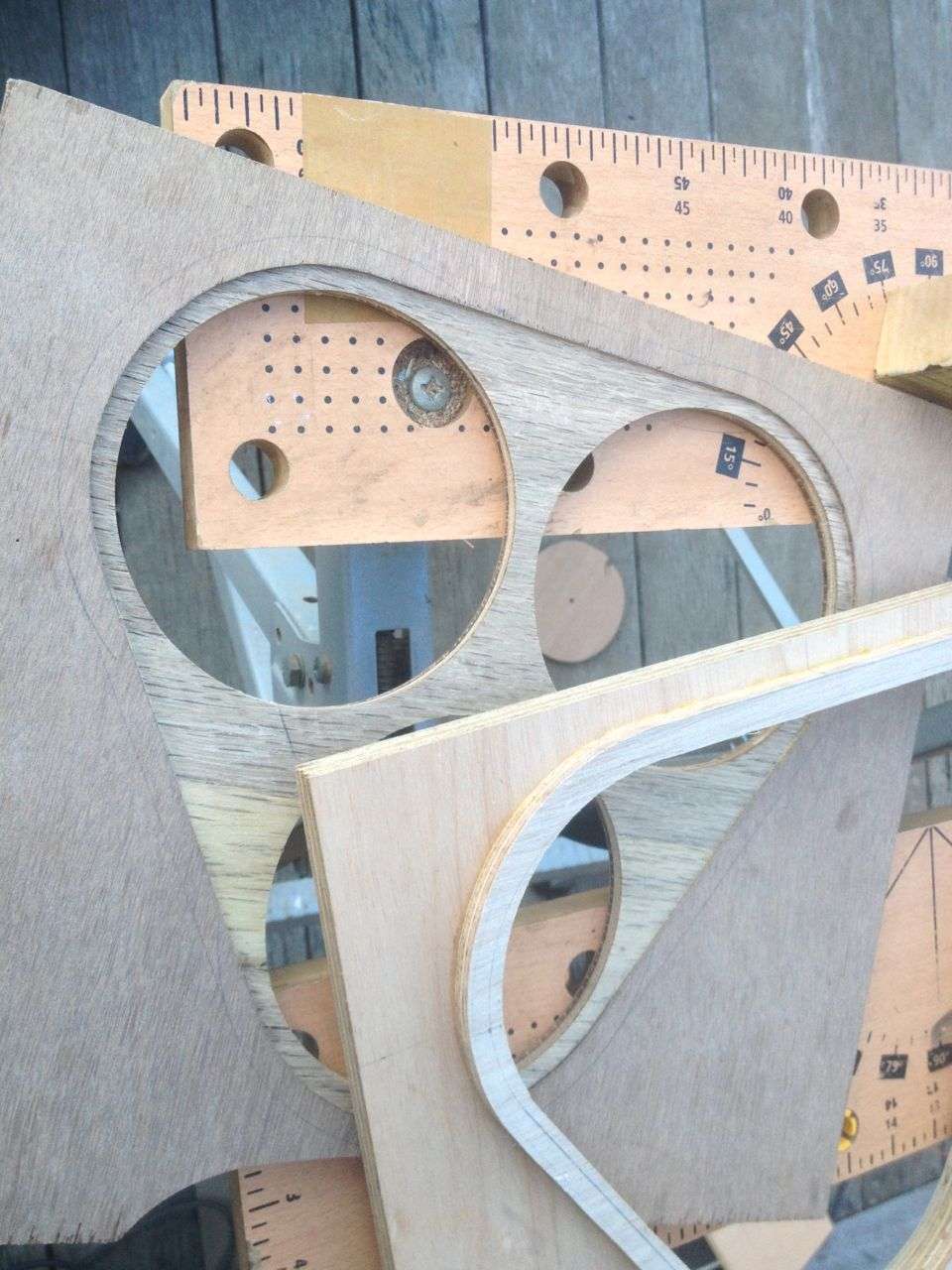

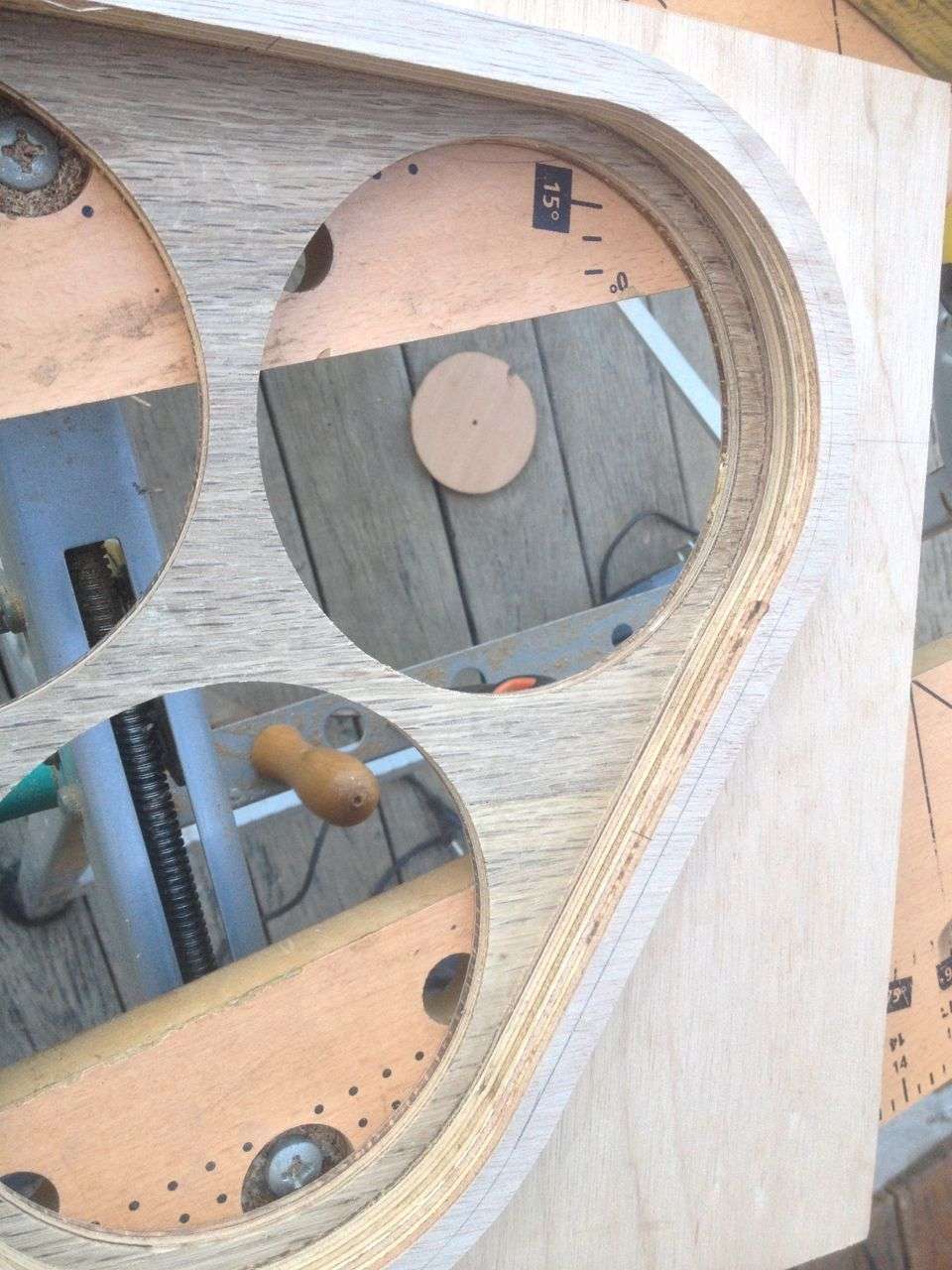

Hollow squareneck wood tricone finished

Re: Next one: Hollow squareneck wood tricone

That's some brilliant craftsmanship ya got going there.

Re: Next one: Hollow squareneck wood tricone

Thanks guys

Azureskys, I feel more tedious than brilliant (but I WANT this tricone... )

)

Richard, maybe I could build another one... later (that's what I said to my wife while building the molds )

)

Actually, I'm just trying to get an acceptable result with this one, but there are not so many more builts like this one to help me on the internet (could'nt find another one, just some with plain necks) so I know nothing about structural strength, sound... that I'll get, I even don't know if I can bend the back to my desired shape... lets say that's a prototype!

Azureskys, I feel more tedious than brilliant (but I WANT this tricone...

Richard, maybe I could build another one... later (that's what I said to my wife while building the molds

Actually, I'm just trying to get an acceptable result with this one, but there are not so many more builts like this one to help me on the internet (could'nt find another one, just some with plain necks) so I know nothing about structural strength, sound... that I'll get, I even don't know if I can bend the back to my desired shape... lets say that's a prototype!

Re: Next one: Hollow squareneck wood tricone

Beautiful work, Xavier. I'm very impressed. You bent the sides the same way I did back in the 60's when I made a Spanish style guitar. Somebody else said as much, that was the way to do it then, I worked from plans sold by Clifford Essex. The back of the guitar looks as if you have book-matched the grain. A very nice touch.

Will C

Will C

-

richard37066

- Posts: 517

- Joined: Sat Dec 11, 2010 11:44 am

- Location: Gallatin, Tennessee, USA

Re: Next one: Hollow squareneck wood tricone

Bend the back to a desired shape? Is it a simple bend or a compound bend? Is the glue that you used to mate the pieces waterproof?

Richard

Richard

Re: Next one: Hollow squareneck wood tricone

Richardrichard37066 wrote:Bend the back to a desired shape? Is it a simple bend or a compound bend? Is the glue that you used to mate the pieces waterproof?

Richard

The glue is titebond

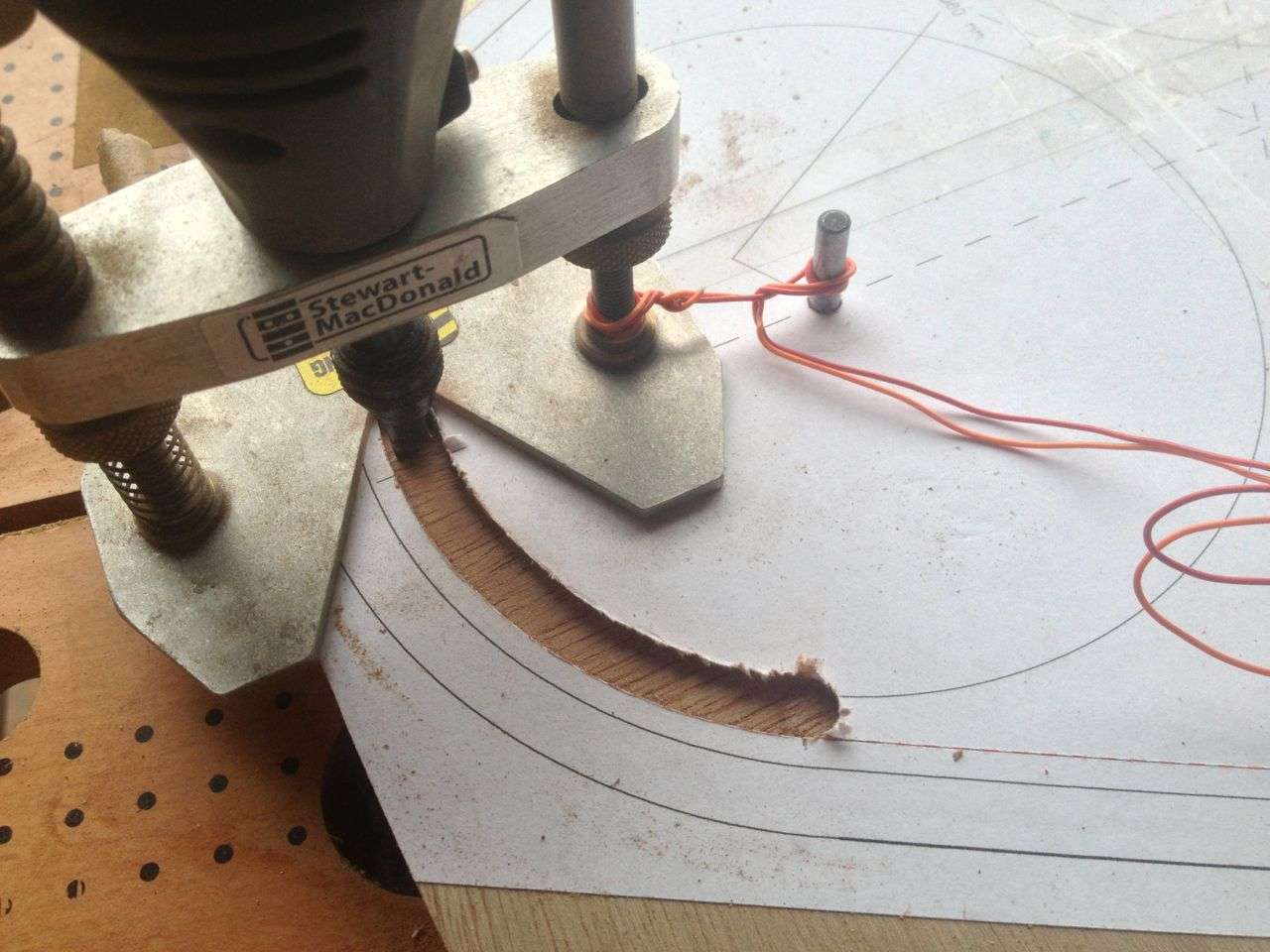

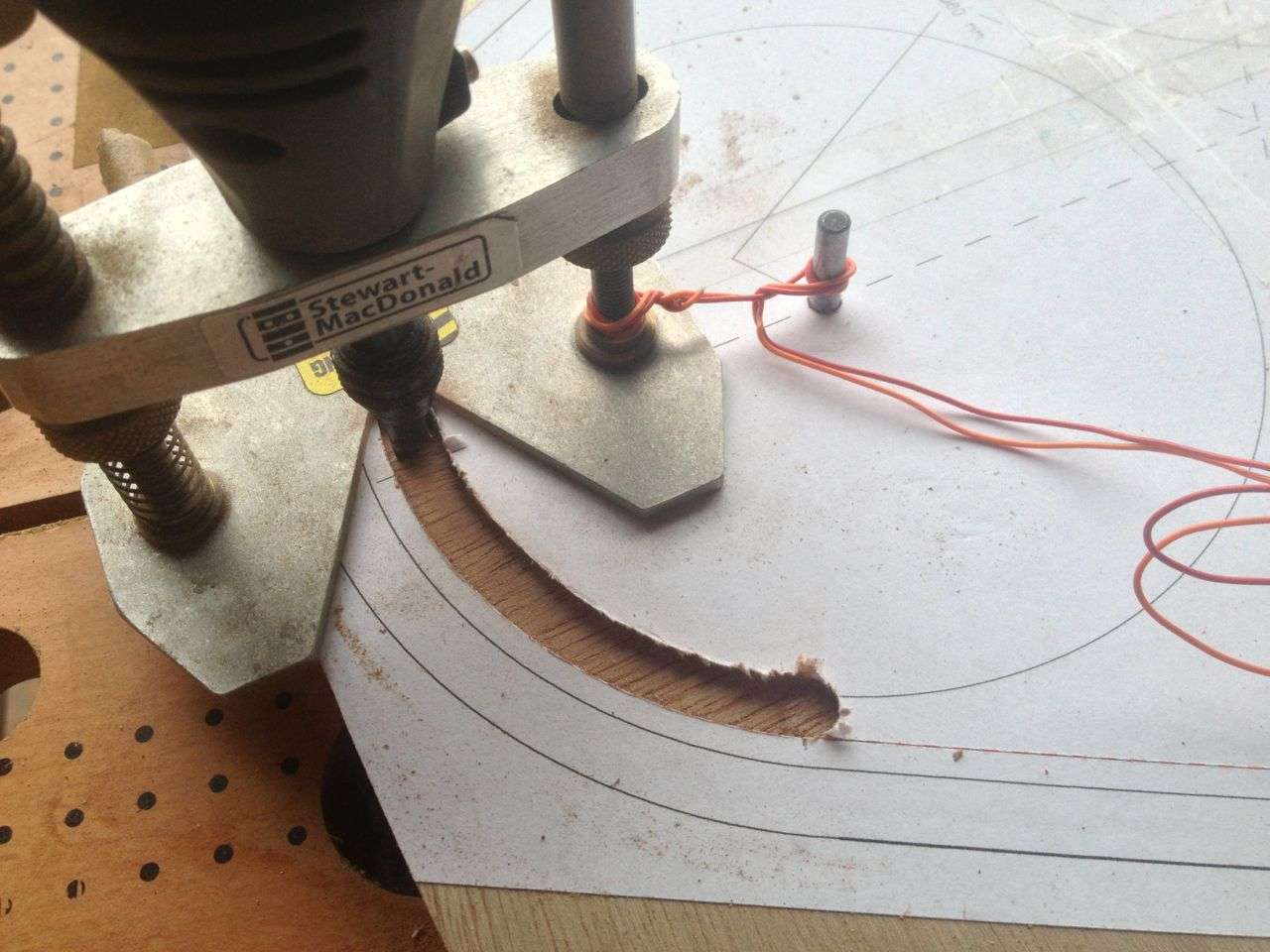

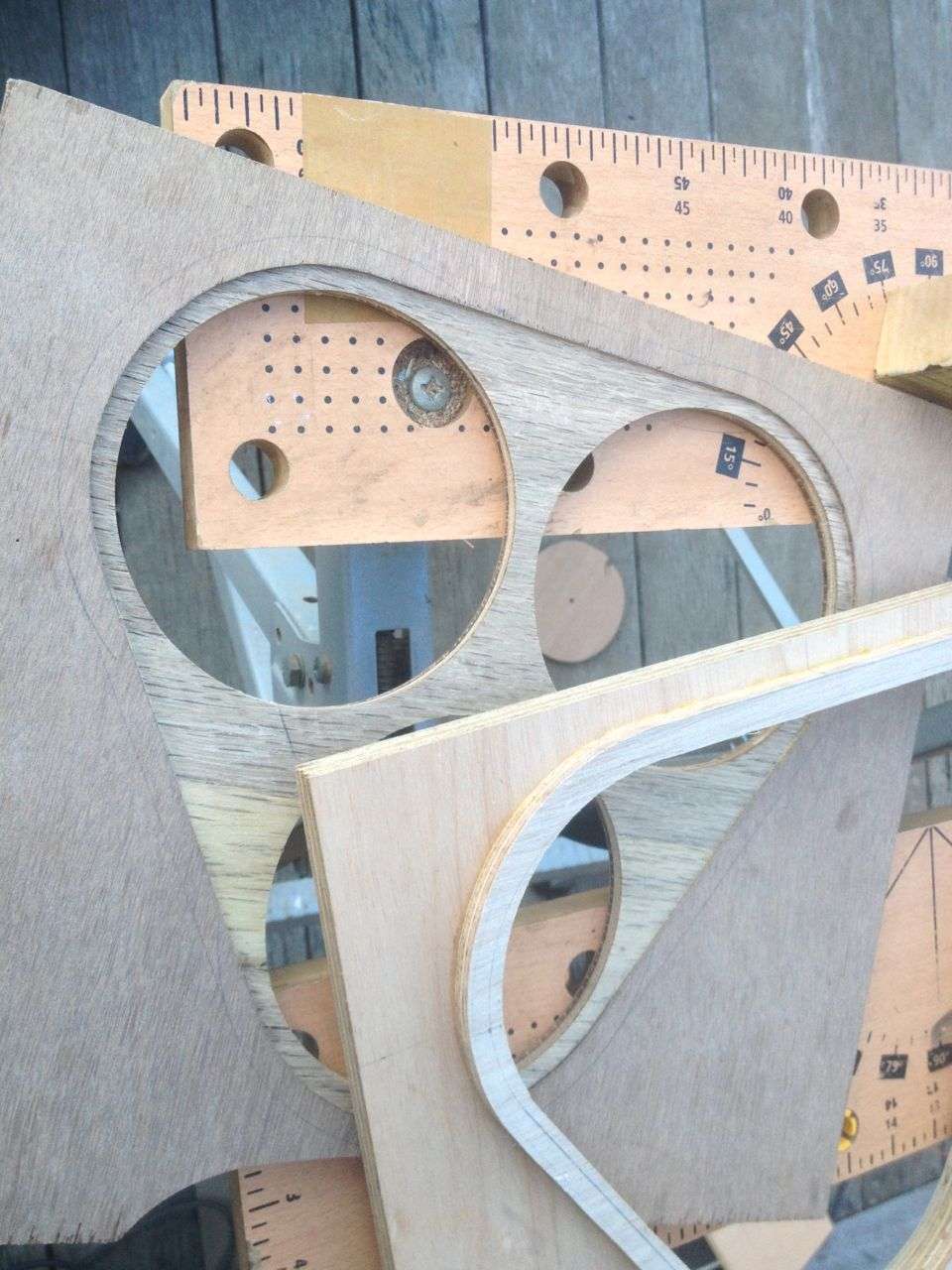

And I think it's a compound bend, take a look at the blueprint:

Xavier

-

richard37066

- Posts: 517

- Joined: Sat Dec 11, 2010 11:44 am

- Location: Gallatin, Tennessee, USA

Re: Next one: Hollow squareneck wood tricone

I'll see if I can help.

Titebond II and Titebond III are recommended for outdoor use - sun, rain etc. Plain old Titebond is not. Which one did you use?

You do not have a compound bend. A compound bend is one in which the wood would be bent in one direction and then bent, again, at 90 degrees to the first. Yours is a simple bend(s) in the direction of the grain.

If you used either Titebond II or Titebond III then I might suggest the following: - Make up a test piece the same thickness as your back. Edge-glued in the center. Make a crude "mold" which is nothing more than a gentle curve in the direction of the grain of a 2X10 or 2X12. Make up a couple of sandbags. The edge-glued piece will be placed on the "mold" with the grain and glue-joint running in the direction of the "bend". Use a spray bottle with plain water to wet both sides of the test piece. Use a "heat lamp" to really warm up the test piece. Caveat: - I do not know whether the heat will soften the glue or not. You're about to find out. Place the test piece on the "mold" and set the sandbags on it - attempting to force the piece to conform to the "mold". Let it sit for at least a day and then pull the sandbags and see if there's any semblance of a bend in the test piece. If there is, then you may have to repeat the process several times. An alternative to the "heat lamp" would be an ordinary clothes steam iron. It just might be too much for the glue joint. Ya gotta experiment.

This is totally unlike my experience with constructing classic guitars some 40+ years ago. I'd place the rosewood sides in the bathtub overnight. After my bending "iron" was hot, I'd commence to making gentle bends - creating steam all the way! But, then, there was no glue joint to be concerned with.

The above may not be the solution to your problem but maybe it will stimulate your thinking such that you can come up with a real, viable means of making those gentle bends.

Hope this helps a little.

Anyone got a better idea? Help this man out!

Richard

Titebond II and Titebond III are recommended for outdoor use - sun, rain etc. Plain old Titebond is not. Which one did you use?

You do not have a compound bend. A compound bend is one in which the wood would be bent in one direction and then bent, again, at 90 degrees to the first. Yours is a simple bend(s) in the direction of the grain.

If you used either Titebond II or Titebond III then I might suggest the following: - Make up a test piece the same thickness as your back. Edge-glued in the center. Make a crude "mold" which is nothing more than a gentle curve in the direction of the grain of a 2X10 or 2X12. Make up a couple of sandbags. The edge-glued piece will be placed on the "mold" with the grain and glue-joint running in the direction of the "bend". Use a spray bottle with plain water to wet both sides of the test piece. Use a "heat lamp" to really warm up the test piece. Caveat: - I do not know whether the heat will soften the glue or not. You're about to find out. Place the test piece on the "mold" and set the sandbags on it - attempting to force the piece to conform to the "mold". Let it sit for at least a day and then pull the sandbags and see if there's any semblance of a bend in the test piece. If there is, then you may have to repeat the process several times. An alternative to the "heat lamp" would be an ordinary clothes steam iron. It just might be too much for the glue joint. Ya gotta experiment.

This is totally unlike my experience with constructing classic guitars some 40+ years ago. I'd place the rosewood sides in the bathtub overnight. After my bending "iron" was hot, I'd commence to making gentle bends - creating steam all the way! But, then, there was no glue joint to be concerned with.

The above may not be the solution to your problem but maybe it will stimulate your thinking such that you can come up with a real, viable means of making those gentle bends.

Hope this helps a little.

Anyone got a better idea? Help this man out!

Richard

Re: Next one: Hollow squareneck wood tricone

Richard,

No, the glue is not Titebond II nor III, just the regular one

I may have to reglue after bending...? the part to bend is short, just at the neck-body junction

the back of the body and neck is straight

The guy that builds these nice guitars:

http://www.flugerguitars.com/hollow%20neck.html

told me he uses steam iron...

No, the glue is not Titebond II nor III, just the regular one

I may have to reglue after bending...? the part to bend is short, just at the neck-body junction

the back of the body and neck is straight

The guy that builds these nice guitars:

http://www.flugerguitars.com/hollow%20neck.html

told me he uses steam iron...

-

richard37066

- Posts: 517

- Joined: Sat Dec 11, 2010 11:44 am

- Location: Gallatin, Tennessee, USA

Re: Next one: Hollow squareneck wood tricone

Went to the Flugerguitars site. That guy has some beautiful looking instruments!

Best suggestion is to make up that test piece that I spoke of and use the iron. See if you can bend it around a mandrel which has a gentle curve. If if falls apart then there's not much lost.

Next best suggestion is to rip the back down the center and then glue it up with Titebond II or Titebond III. See how much info you can glean from their site so as to pick the best one.

Wish that I could help more.

Richard

Best suggestion is to make up that test piece that I spoke of and use the iron. See if you can bend it around a mandrel which has a gentle curve. If if falls apart then there's not much lost.

Next best suggestion is to rip the back down the center and then glue it up with Titebond II or Titebond III. See how much info you can glean from their site so as to pick the best one.

Wish that I could help more.

Richard

Re: Next one: Hollow squareneck wood tricone

Thanks for your help Richard

The first thing I'll do is routing/sanding the back down th 2.2-2.5 mm thickness before any bending attempt

Xavier

The first thing I'll do is routing/sanding the back down th 2.2-2.5 mm thickness before any bending attempt

Xavier

Re: Next one: Hollow squareneck wood tricone

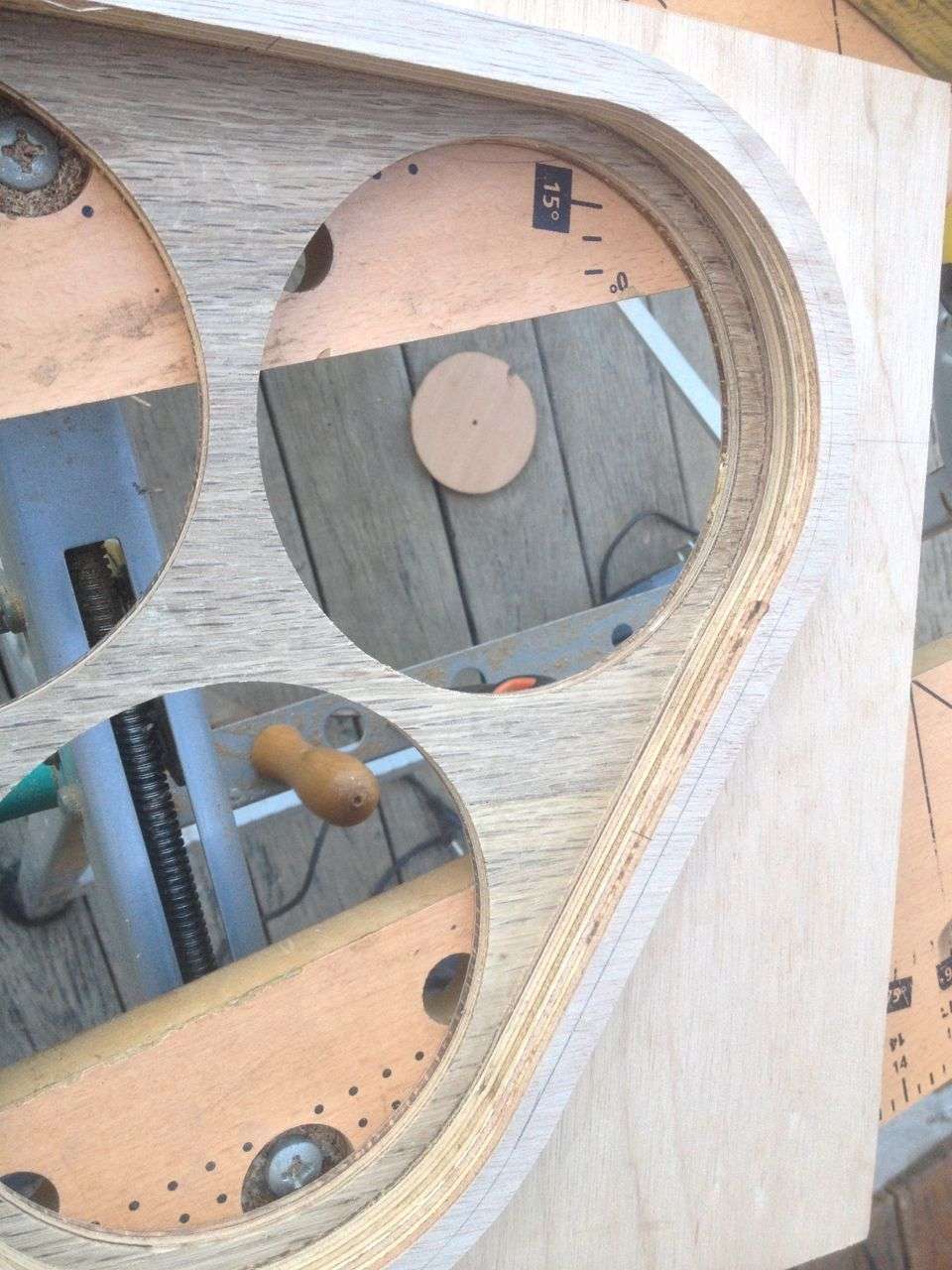

The well is almost finished