Page 2 of 2

Re: finishing cross shaft ends

Posted: Tue May 14, 2013 11:09 am

by ljs

There you go....a picture is worth a thousand of my postings.....Not much of an angle and as far as I can see no problems in the application of the cross-shaft and the bushings. As I said way back then a pretty clever tool. Thanks farmer.

LaVern

Re: finishing cross shaft ends

Posted: Mon Jun 17, 2013 7:21 am

by bluesteel

Yes, nice work. I did get the quarter inch hollow mill, and the seller threw in another for free - nice guy from the French part of Canada. The inside diameter is not the 8 or 9mm that I see on most cross-shafts, but I figure that a quarter inch is still way enough meat to allow it to work in a nylon or acetal bush provided I make sure there is a little clearance, as nylon is hygroscopic.

Re: finishing cross shaft ends

Posted: Thu Oct 03, 2013 12:04 pm

by pickgetter

Hi! I'm a retired machinist of 43 years in the trade, and have a metal lathe and small Bridgeport type mill, at home.Turning the ends of a square shaft, is very simple. Of course, a 4 jaw lathe chuck is the simple solution, but if you only have a 3 jaw chuck, here's a easy solution, that works great. Take a short piece of round stock, (steel , brass , or aluminum) about an inch or more , in length , and drill , or bore a hole, thru it , the size , that the square stock will just fit thru snugly . Now take it out of the lathe, and hack saw a slot down the length of the tube .Put it back in the lathe chuck, and slip in your square stock, and tighten the chuck. The sawed slot, will close just enough to snugly hold your shaft, while you turn the ends, to the size required for your bearings, or bushings. and, will be perfectly centered , to the square stock. I have built an S-10, with 3 pedals, and 4 knee levers, and all my square, cross shafts, are turned this way. It's way faster than changing chucks, and playing with the 4 jaws, , trying to get the square stock centered.

Re: finishing cross shaft ends

Posted: Mon Jun 02, 2014 3:29 pm

by bluesteel

Well, I tried my theory about the diameter of the machined round portion of the cross-shaft. I have my 6.5mm hollow mill in an ER25 collet chuck in the tailstock of my little Chinese lathe. The square section cross-shaft is held in the 3-jaw chuck by the time-honoured fashion of putting it in a short piece of tube that is a snug fit, and slotted along its length. It tightens up just fine and holds the piece of square shaft nicely central. That hollow mill cuts a lovely centred spindle on the end and it does not seem to me that 6.5mm is insufficient diameter. Time will tell. I'm delighted with how this little test went. Another step closer to the build.

Next job: a tool to hold the pivoting parts of the changer (the ones that the string runs over and anchors to) and pivot them past the cutter in the mill, so that I can cut accurate repeatable half-circle profiles on them. You can never have too many good tools.

Re: finishing cross shaft ends

Posted: Tue Jun 03, 2014 8:17 pm

by Bent

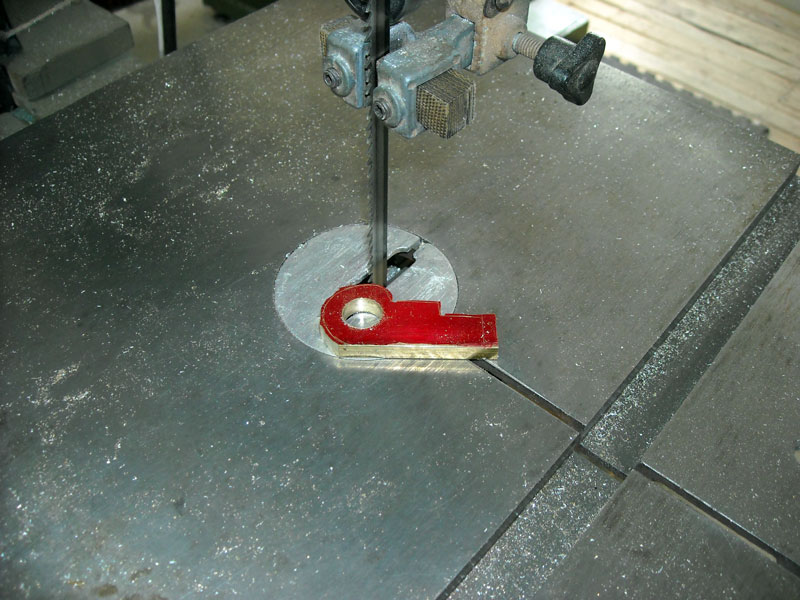

Will. here might be an answer to your question re making the rounds on the string finger, as well as the rounds on the raise bar.

I have drilled the hole for the 1/2" changer axle. I have also rough-cut the finger on the band saw, including the round, as you see in the first pic. Next I machine all the flat surfaces. I gang up 10 fingers on a short piece of 1/2" drill rod, clamp them in the vise and machine them all to fin. measurements.

- fingerbndsw.jpg (110.4 KiB) Viewed 8255 times

Here is the jig for the rounding:

- FingJig.jpg (76.85 KiB) Viewed 8255 times

This jig is simply a piece of square 1/2" aluminum into which I have press-fit a short piece of 1/2" drill rod for the finger to pivot on. Notice how the finger is spaced up from the plate by a 1/16" nylon washer. See also the angled handle that I screw securely on to the machined parts of the finger. I like this handle to be angled in order to avoid reaching around the cutter. Line up center of end mill with center of drill rod piece.with every thing in place and ready to go, do a dry run to ensure you are taking a very small cut. Cutting is done by the conventional milling method. NO climb milling here!! I don't get too greedy. Take a .015" cut til you get the feel for it. Then turn the finger against the cutter. The cut is actually a 180 degree pivot. When you get toward the end of your finish cut, make shallow cuts of .010" for a better finish.The last cut will be when you have advanced the table so that the cutter is barely tickling the edge of the finger. Bring the finger around and you're done. Now is the time to set your dial indicator (or digital readout) to "0". This is what decides the stopping point for the successive fingers.

I use a 1/2" 4-flute end mill at 1120 RPM. Keep control of handle at all times, never let it go.

Check the hold-down screw for correct tightness . You don't want the finger to wobble.

Re: finishing cross shaft ends

Posted: Sat Jun 07, 2014 5:27 pm

by bluesteel

Bent. that's pretty much per my drawing: great minds think alike, they say. I just got the plate to make the tool. A swinging arm to clamp the changer finger to, but my thing has a half inch diameter pivot pin at the centre and two stops, one either side, for the swinging arm to contact.

This defines the start and end of the half circle. Like you, I could see the workpiece has to be spaced up off the plate that holds the pivots, to avoid cutting into the baseplate. Cutting all the straight faces as one piece ensures repeatability so the fingers are interchangeable.

I'll post a photo of my method of cutting cross-shaft ends tomorrow.

Re: finishing cross shaft ends

Posted: Sun Jun 08, 2014 3:41 pm

by bluesteel

Here's my setup for cutting the end of square cross-shafts circular. It's quick, easy and repeatable. I just need to fit a cheap DRO to the tailstock so I can accurately measure the degree/depth of cut. I have one, it's one of those "too many jobs, not enough time" situations.